Consider a facility that faced a significant electrical fire due to outdated wiring—an incident that could've been prevented with a thorough annual safety audit. You need to understand that these audits aren't just bureaucratic requirements; they're essential for identifying potential hazards and ensuring compliance with safety regulations. By systematically evaluating electrical systems and maintenance practices, you can enhance workplace safety. The real question is, what key components should you focus on during these audits to effectively mitigate risks and protect both employees and assets?

Importance of Safety Audits

When it comes to ensuring a safe working environment, the importance of safety audits can't be overstated. These audits play an essential role in identifying potential hazards and ensuring compliance with electrical safety standards. You'll find that regular audits help you detect issues before they escalate into serious problems, thereby protecting both your employees and the organization.

By conducting safety audits, you're not just adhering to regulations; you're fostering a culture of safety that prioritizes employee well-being. These audits enable you to evaluate the effectiveness of your current safety protocols, ensuring that they align with industry best practices. In addition, they provide an opportunity for continuous improvement, allowing you to adapt to new technologies and methodologies.

Safety audits also enhance your organization's reputation. By demonstrating a commitment to safety, you build trust with employees, clients, and stakeholders. This can lead to improved morale and productivity, as workers feel secure in their environment.

The financial benefits are significant too; reducing accidents can lower costs associated with workers' compensation claims and insurance premiums. Ultimately, regular safety audits are an investment in both safety and operational efficiency.

Key Components of Audits

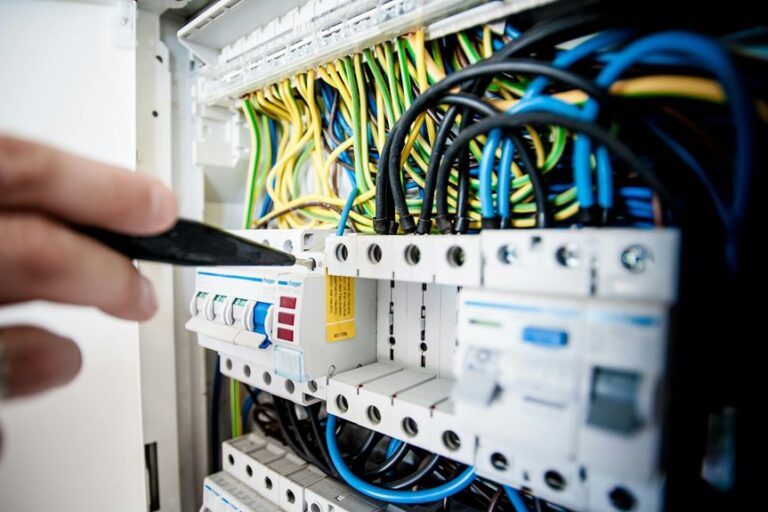

Understanding the key components of electrical safety audits is crucial for maximizing their effectiveness. First, you need to conduct a thorough inspection of all electrical systems. This includes reviewing wiring, circuit breakers, and grounding systems to identify potential hazards.

Next, evaluate maintenance records; verify that all equipment has been regularly serviced and repaired as needed.

Another critical component is the assessment of employee training. You should confirm that all personnel understand safe operating procedures and emergency protocols. Regular training sessions help keep safety top of mind and promote compliance with safety standards.

Documentation plays a significant role in audits. You must maintain accurate records of previous audits, inspections, and any corrective actions taken. This not only helps track compliance but also provides a clear history of your electrical safety measures.

Lastly, you should implement a follow-up procedure. After the audit, address any identified issues promptly and re-evaluate your systems to facilitate continuous improvement.

Compliance and Regulations

Compliance with electrical safety regulations is crucial for any organization aiming to protect its employees and assets. You must stay informed about local, state, and federal regulations that govern electrical safety, such as the National Electrical Code (NEC) and Occupational Safety and Health Administration (OSHA) standards.

These regulations set forth requirements for safe electrical installations, maintenance, and inspections, guaranteeing that your workplace meets established safety criteria.

Ignoring these regulations can lead to serious consequences, including fines, legal liabilities, and increased risk of accidents. To maintain compliance, you should regularly review safety protocols, conduct training sessions for employees, and confirm that all electrical equipment is up to code.

It's also essential to document your compliance efforts meticulously. Keep records of inspections, maintenance, and any corrective actions taken. This documentation serves not only as proof of compliance but also as a valuable resource for future audits.

Implementing Annual Audits

Annual audits play an essential role in maintaining electrical safety standards within your organization. To implement effective audits, start by establishing a clear schedule. Choose a specific time each year to conduct your audit, guaranteeing it aligns with your operational calendar. Assemble a qualified team familiar with electrical safety regulations and your facility's specific requirements.

Next, define the scope of the audit. This should include all electrical systems, equipment, and safety protocols in place. Create a checklist that encompasses critical areas such as grounding, circuit integrity, and emergency systems. Utilizing this checklist helps maintain consistency and thoroughness.

During the audit, document findings meticulously. Note any discrepancies, potential hazards, and areas for improvement. After completing the assessment, hold a debriefing session with your team to discuss results and prioritize corrective actions.

Finally, develop an action plan addressing identified issues with clear timelines and responsibilities. Regularly review and update your audit process to reflect any changes in regulations or company operations.

Benefits of Regular Audits

Regular audits offer significant advantages for enhancing electrical safety within your organization. By conducting these assessments regularly, you identify potential hazards before they escalate into serious issues. This proactive approach not only mitigates risks but also protects your employees and assets.

Furthermore, regular audits guarantee compliance with local and national safety regulations. Keeping up with these standards helps you avoid fines and legal repercussions while fostering a culture of safety. You'll also enhance your organization's reputation, demonstrating your commitment to safety and reliability.

Another benefit is the opportunity for continuous improvement. Each audit provides insights into your electrical systems, allowing you to implement best practices and upgrade outdated equipment. This not only increases operational efficiency but also prolongs the lifespan of your electrical infrastructure.

Moreover, regular audits help in training and educating your workforce. They reinforce safety protocols and raise awareness about electrical hazards, which is vital for maintaining a safe work environment.

Conclusion

In summary, conducting electrical annual safety audits is like maintaining a car; regular check-ups prevent breakdowns and guarantee smooth operation. By prioritizing these audits, you not only comply with regulations but also create a safer work environment for everyone. The benefits extend beyond mere compliance—proactive assessments reduce risks, enhance training, and ultimately protect your organization from costly liabilities. Make safety audits a routine part of your operations, and you'll foster a culture of safety that pays dividends in the long run.